This video is also available on YouTube here:

If you only want the instructions for mixing Plaster of Paris please go directly to the video. If you would like to understand more about the chemistry, manufacture, physical characteristics, and some tips for re-enforcing, coloring, dangers, and proper disposal, please read on.

The basis for this post is that I have checked several sites for the instructions and found them wrong, misleading, or lacking in good information about this versatile casting material. Plaster of Paris has been in use for well over 5 thousand years and is still misunderstood. So, while I am not an expert, I have used this material for years with good success and continue to find new uses.

Plaster of Paris is made from calcium sulfate dihydrate, (CaSO4.2H2O), frequently called gypsum. This simply means that there are two molecules of water with each calcium sulfate. It is a naturally occurring mineral found in many locations around the world but was originally named after a large deposit in Montmartre near Paris. The dihydrate is ground and roasted at 150 C (300F) to drive off 1 and ½ molecules of water as steam. The modified material is now calcium sulfate hemihydrate, Plaster of Paris, and has only ½ a molecule of water, 2CaSO4·2H2O + Heat → 2CaSO4·½H2O + steam. Since it takes in energy as heat it is an endothermic reaction. So, when we buy Plaster of Paris, we are buying the hemihydrate of calcium sulfate. In order to make it a castable solid we add water so that it becomes the dihydrate again! The Plaster of Paris gives off the energy that it has stored and when setting into a solid provides an exothermic reaction. It can become very hot and can burn exposed skin. So, it is not used as a casting medium for human parts casting. When it is used as a cast for broken limbs it is used over bandage material and not in direct contact.

Plaster of Paris is a very soft mineral although it can be relatively strong when it is used as a cast. On the Mohs scale of mineral hardness, with talc being 1 and diamond being 10, Plaster of Paris is a 2. This allows it to be sanded, trimmed, and damaged easily. Once set, it is not water soluble, and it has a very low rate of expansion, about 0.1 %. It sets or hardens in a monoclinic crystal lattice which means that the particles are all facing the same direction. This provides a dense cast, but there are still interstitial areas and it is porous.

Plaster of Paris sets in a very short period of time depending on the temperature of the mix and the air temperature. Typically, it can be de-molded in about 30 to 45 minutes. If it is cool to the touch it has at least set. But, set time is not the same as cure time. In order to fully cure, the cast will usually take between 48 and 72 hours with good ventilation to allow any excess water to escape. There is a great deal of speculation on the web about increasing set time. I have seen everything mentioned from baking powder to vinegar. But, adding other chemicals will change the material characteristics and may lead to failure due to interruption of the crystal lattice. The best methods to increase the working time is to use cold water, use short mixing times, or by using an excess of water. It is also possible to purchase Plaster of Paris with retardants that are designed to increase working time. But, by using cool water, and short mixing times, I have had material that had a working time of 30 minutes.

Plaster of Paris can be strengthened by using glass fiber, gauze bandage, or other suitable material. In fact, there is a product called modrock that is coated with plaster and simply moistened to use. It is also easy to color the plaster with poster paint or tempera. But, use caution as some colors can cause an almost instant set time. Food color would be a poor choice as it is not color fast.

Plaster of Paris is a fine powder and should not be inhaled. Pour material slowly and use a mask if you feel the need. But, it is a safe material with great casting potential. One serious caution is to dispose it as the solid and not put it in a drain as it will clog the pipes.

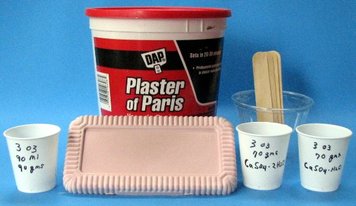

If there are any facts that I failed to include please use the comments section to ask questions or add any other useful information. Now, let get mixing!

RSS Feed

RSS Feed