Milk is a blend of several naturally occurring ingredients including fat, protein, and sugar. Milk is a colloidal suspension which simply means that the fat and protein molecules are very small and are floating around freely and not attached to each other. The light is refracted in this colloid and that is why it appears white. We can consider the protein molecules (casein) to be a monomer that can potentially be attracted to each other to become a polymer. There will be more on the polymer later in the post.

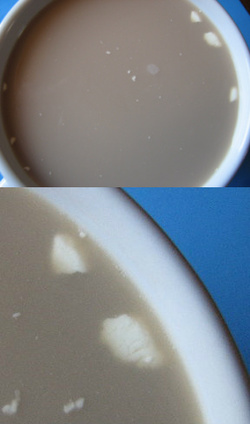

So, in milk the casein molecules are floating around individually and naturally repel each other. But, if the milk becomes more acidic (lower pH) the casein molecules attract each other and begin to clump or curdle. They separate from the liquid portion now called whey. And, as in most chemical reactions, increased temperature accelerates the clumping. But that fails to explain how the milk becomes more acidic. All milk whether pasteurized or not contains bacteria. It is harmless and just swims around doing something that can change the milk over time. Hence, the “sell by” or “use by” date on the container. The bacterium slowly eats the natural sugar in milk called lactose. One of the byproducts of the bacterial feast breaks lactose down into lactic acid and the pH drops. And, as the pH drops the clumps increase, and the milk will spoil. Actually, it is the smell of lactic acid that indicates spoiled milk. So, if the clumps are only sporadic in number and the milk smells normal, it is fine to use the milk. But, it is an indicator that the milk is on the way over the hill! But, the good news is this is exactly how some cheese is made. The milk is heated and an acid is added like vinegar or lemon juice and the curd is separated from the whey. But, what about the above mentioned casein polymer?

Well, as the lactic acid forms the curds, the individual casein monomers unfold and reassemble in a connected chain forming a polymer or plastic. When the curd is kneaded and the water removed, the mass can be molded and shaped and will become hard. But, it is very biodegradable and will break apart with water. However, chemists in the early 1900’s discovered that they could make a more permanent and functional product by washing the curds in a 5 % solution of formaldehyde to cross link the polymer. These products (referred to as the Galalith process) were sold as buttons, fountain pens, and other decorative items for over 70 years. So, with milk we can make butter, cheese, yogurt, and pour it in our coffee and cereal!

If you want to make your own bioplastic from milk and vinegar, just search “casein plastic”, or “milk plastic”. There are multiple sites to show you how. Got Milk?

RSS Feed

RSS Feed