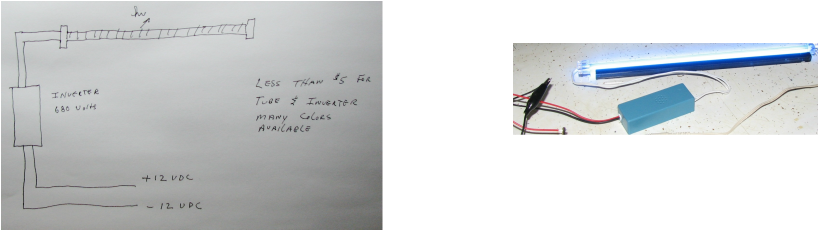

How do they work? A cold cathode lamp functions by using electricity emitted from the cathodes to excite mercury vapors using the process of inelastic scattering in order to create fluorescence, just as a typical linear fluorescent does. What sets the cold cathode lamp apart is that by using higher voltage, a cold cathode lamp does not require the cathode to be heated in order to fire and produce light. This allows it to draw less current, run cooler, and last longer. They can be very bright, do not flicker, and are totally dimmable.

RSS Feed

RSS Feed